An oil mist eliminator that reduces maintenance to a minimum

The advantages with 3nine oil mist eliminators are many. Among them is the minimal yearly maintenance compared to other technologies and money saved on replacing oils/coolants as all separated fluid is returned directly back to the machine tool for reuse.

Why should you spend time and money on maintenance?

Practically every supplier of an oil mist solution can offer 99.95% clean air by using a HEPA-filter grade H-13 as an end filter. However, what happens between your filter changes, and how often do you need to complete this task? What is the cost and time that it takes to perform this maintenance and safely dispose of this bio-hazardous waste? These are the questions that you need to ask yourself before you determine which system to utilize in handling oil mist. Since 3nine units separate oil particles down to 1μm from the air and return them back to the machine tool tank, many of our customers have pushed off their weekly maintenance of oil mist collectors to every two or three years.

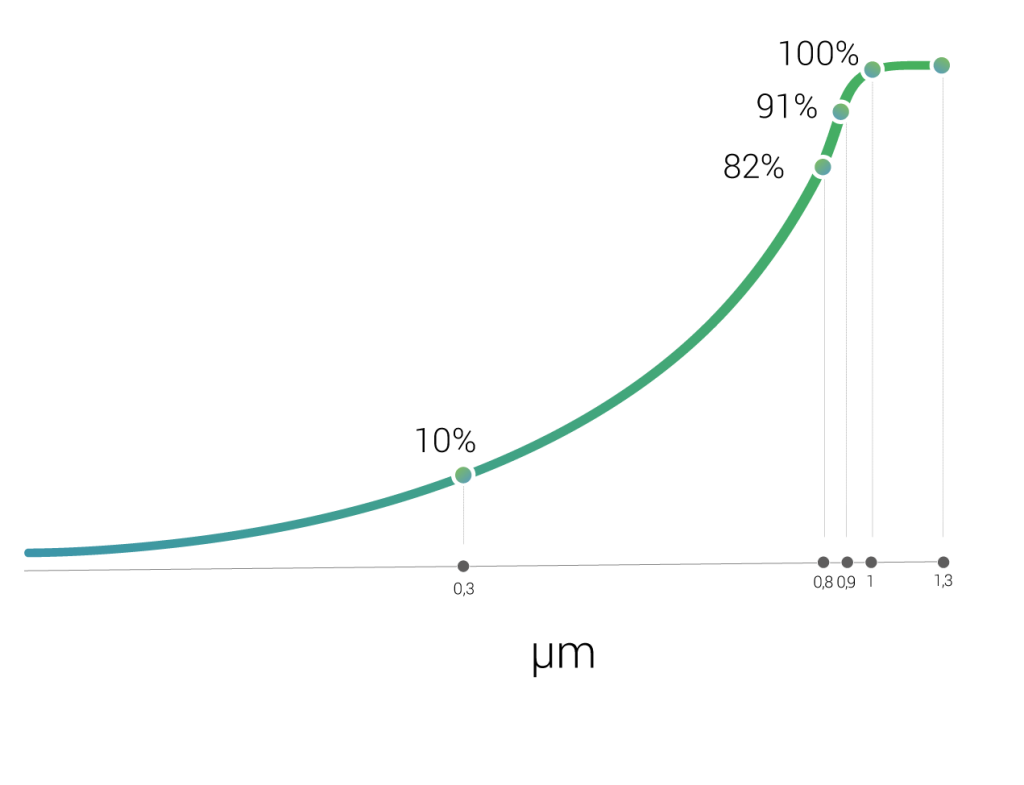

High separation of oils and coolants

No other solution on the market has the high degree of cleaning efficiency as 3nine's oil mist eliminators. 100% of all fluid particles down to 1 μm are separated out and are immediately recycled for reuse. Our technology even allows for a proportion of the particles less than a micron to be separated out such as 82% of all particles down to 0.8 μm!

Low filter consumption

We estimate that the average filter life on our oil mist eliminators is more than 30 months but oftentimes we can exceed this. The filter life varies depending on its usage/application and could potentially have a lifetime of 3 months to 6 years. If you are using low viscosity oil, high-pressure coolant, or high spindle speeds this will affect the size of the oil particle, producing mainly particles smaller than 1 μm, which is smoke. In other words, these factors will reduce the life of your filter. We do not want to sell you false promises because we can’t predict the ratio of oil mist vs. oil smoke, but we want you to understand how innovative our products can be in your everyday life. Since we started in 2003, we have sold 13,000 oil mist eliminators and only 25,000 filters. This is two filters per each oil mist eliminator, indicating a longer filter life than above’s 30 months. Our customers remain with us because they note the value that 3nine technology has introduced into their lives, how little time and money they need to spend on maintenance. We save you time and money where other companies cannot fulfill those promises.

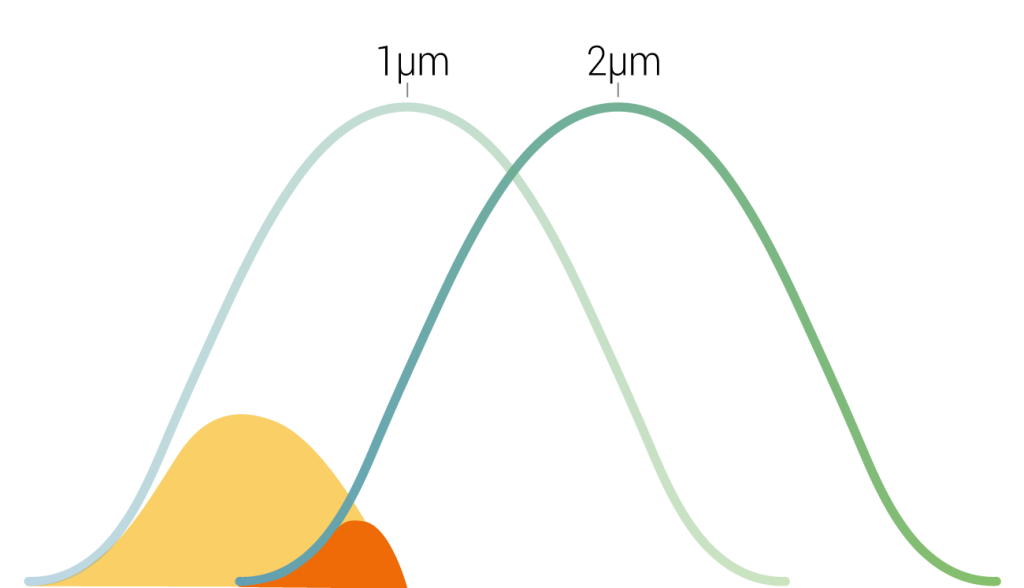

High pressure coolant application

As seen in the chart to the right, a standard application has a concentration of particles of approximately 2μm. In these cases, almost everything is separated out, and only a small part becomes smoke and goes into the filter (orange section). But with a high-pressure coolant machining the curve will shift to the left and the particle concentration will instead be around 1µm or smaller, which will utilize the HEPA more to collect smaller particulate (yellow section). By using a larger eliminator and reducing the airflow, one can increase the separation of smaller particles. This means that the 3nine oil mist eliminators are a great solution for high pressure coolant machining.

Working with high pressure coolant? Let's discuss a solution

Low risk for fire hazards

Not many people know or think about the greater fire risks with long pipe runs. Mechanical and Central filtration solutions normally have long pipe runs to get the processed air as dry as possible before the filter. With that you should know that the oil mist settles in the pipes and as a result can create the risk of a fire, unless properly maintained. Long piping should therefore always be avoided when dealing with oil mist. Our machines can be installed directly on top, on the side or right next to the machine tool, so as to be as close to the oil mist source as possible.

Go to products Check out our products and why not submit a request for quote