Anna 600

The oil mist eliminator Anna effectively cleans the oil mist formed during the CNC metal working process. Besides dispensing clean air into the workshop, the Anna recycles almost all of your oil/coolant separated.

The Anna is suitable for all applications involving processes using oil, coolants or other lubricants. Even with tough applications such as grinding and machining of cast iron you can expect a 99.95% particle-free air. Read more about how this is possible under the Technology section.

The Anna works on all machine tools with a cabin volume of up to 212 CF (6 m³ ) and can be installed directly on top of the machine tool, on the side, on a wall/column or on a pillar stand. See examples on how others have installed their Anna further down on this page.

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <6m3 |

| Airflow | 600m3/h |

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | 210CF |

| Airflow | 352CFM |

| Unit | Anna 600 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <6m3 |

| Airflow | 600m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 3-phase, 380-480V, 50/60Hz, 6A |

| Motor rating | 0.75kW |

| Rated current | 1.9A |

| Speed | 6700 rpm |

| Lenght | 748 mm |

| Depth | 546 mm |

| Height | 936 mm |

| Weight | 80 kg |

| Inlet pipe | Ø 200 mm |

| Sound level | <70 db (A) |

| Unit | Anna 600 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | 210CF |

| Airflow | 352CFM |

| Operating condition | 41-122 F |

| Electric power supply | 3-phase, 208-240V, 50/60Hz, 6A |

| Motor rating | 0.75kW |

| Rated current | 1.9A (230V) – 3.3A (460V) |

| Speed | 6700 rpm |

| Lenght | 29.5” |

| Depth | 21.5” |

| Height | 36.9” |

| Weight | 176.4 lbs |

| Inlet pipe | Ø 8” |

| Sound level | <70 db (A) |

The oil mist eliminator Anna effectively cleans the oil mist formed during the CNC metal working process. Besides dispensing clean air into the workshop, the Anna recycles almost all of your oil/coolant separated.

The Anna is suitable for all applications involving processes using oil, coolants or other lubricants. Even with tough applications such as grinding and machining of cast iron you can expect a 99.95% particle-free air. Read more about how this is possible under the Technology section.

The Anna works on all machine tools with a cabin volume of up to 212 CF (6 m³ ) and can be installed directly on top of the machine tool, on the side, on a wall/column or on a pillar stand. See examples on how others have installed their Anna further down on this page.

| Unit | Anna 600 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <6m3 |

| Airflow | 600m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 3-phase, 380-480V, 50/60Hz, 6A |

| Motor rating | 0.75kW |

| Rated current | 1.9A |

| Speed | 6700 rpm |

| Lenght | 748 mm |

| Depth | 546 mm |

| Height | 936 mm |

| Weight | 80 kg |

| Inlet pipe | Ø 200 mm |

| Sound level | <70 db (A) |

| Unit | Anna 600 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | 210CF |

| Airflow | 352CFM |

| Operating condition | 41-122 F |

| Electric power supply | 3-phase, 208-240V, 50/60Hz, 6A |

| Motor rating | 0.75kW |

| Rated current | 1.9A (230V) – 3.3A (460V) |

| Speed | 6700 rpm |

| Lenght | 29.5” |

| Depth | 21.5” |

| Height | 36.9” |

| Weight | 176.4 lbs |

| Inlet pipe | Ø 8” |

| Sound level | <70 db (A) |

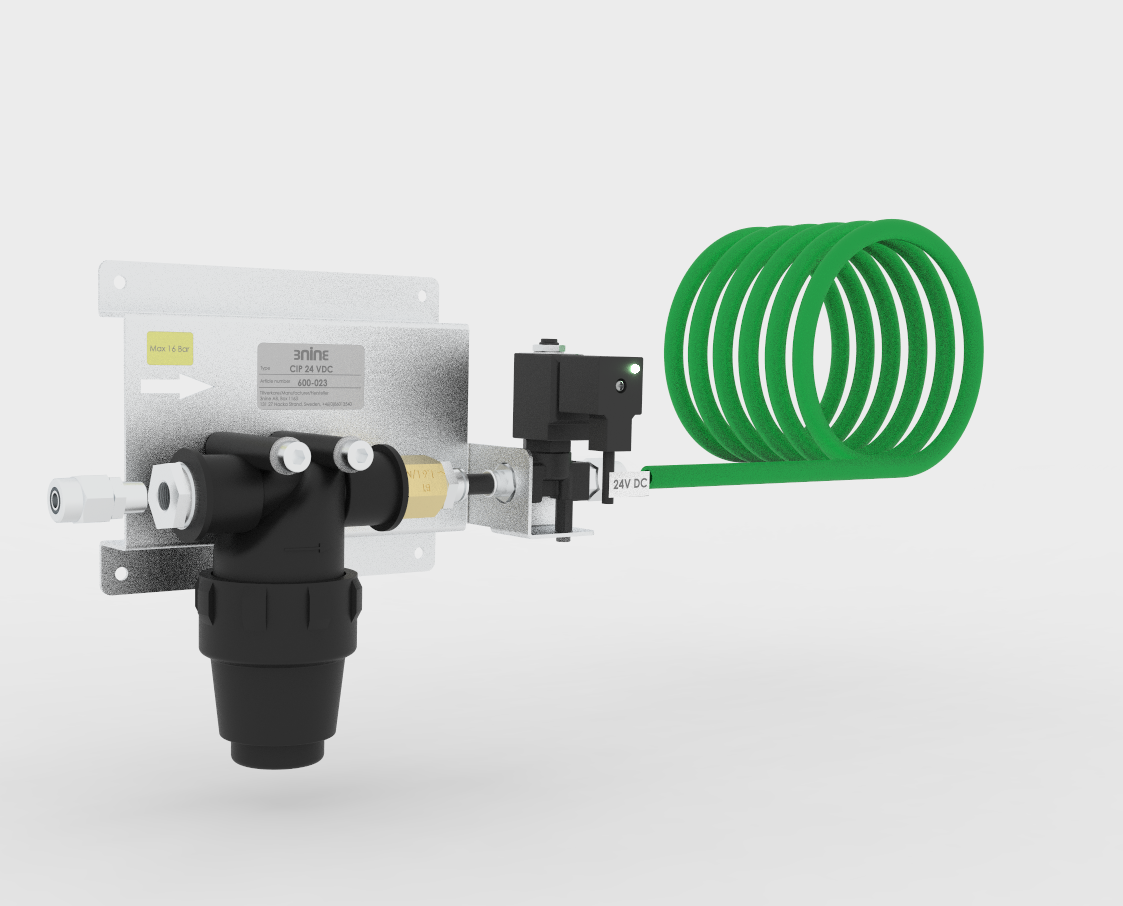

Accessories and spare parts

Installation images

Triangle Engineering Inc., USA

"Our first Clara was installed over a year ago, and has required ZERO maintenance. We now have three 3nine units installed, and our shop air is noticeably cleaner. The fact that the units are quiet and mounted directly on our machines is a bonus."