Lina 500

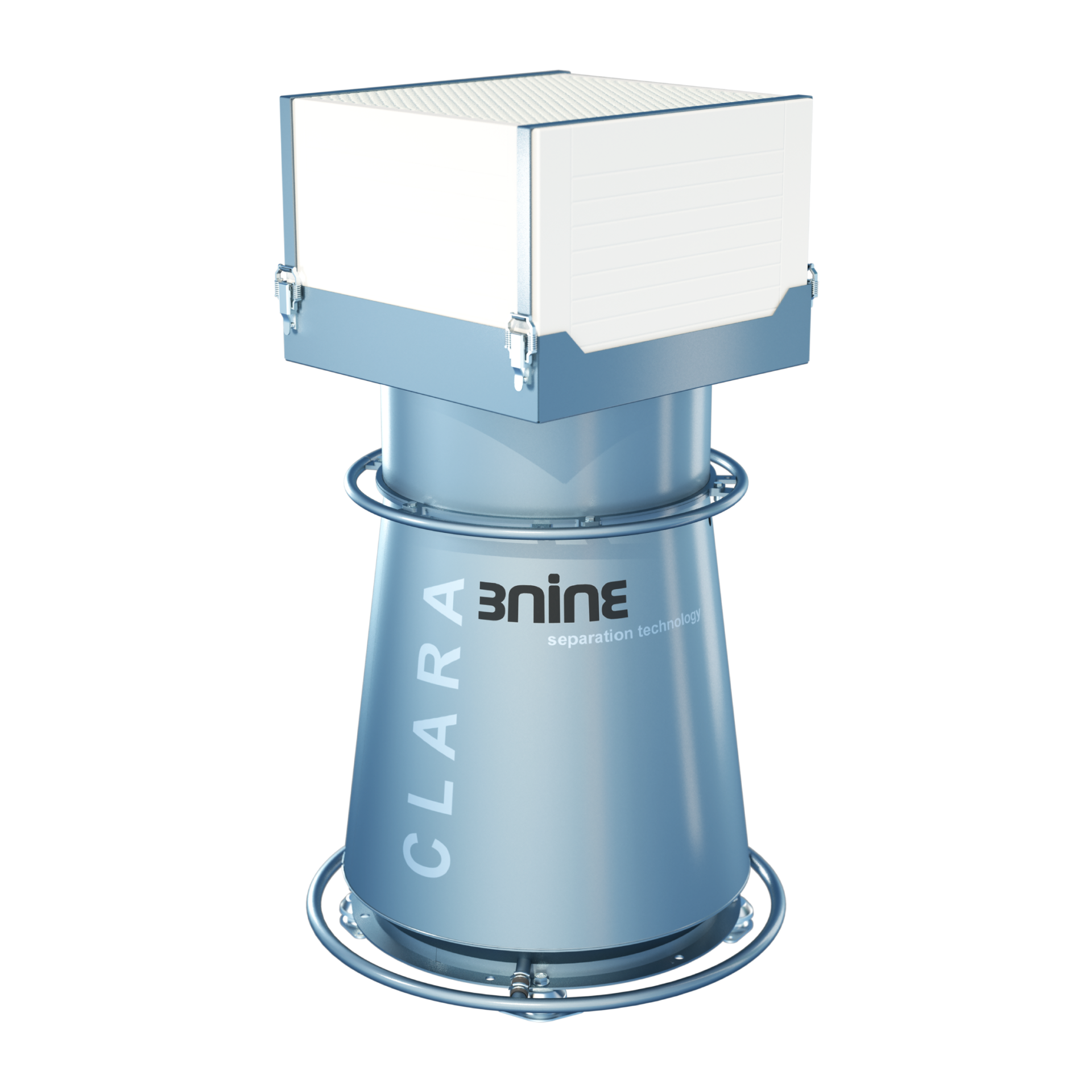

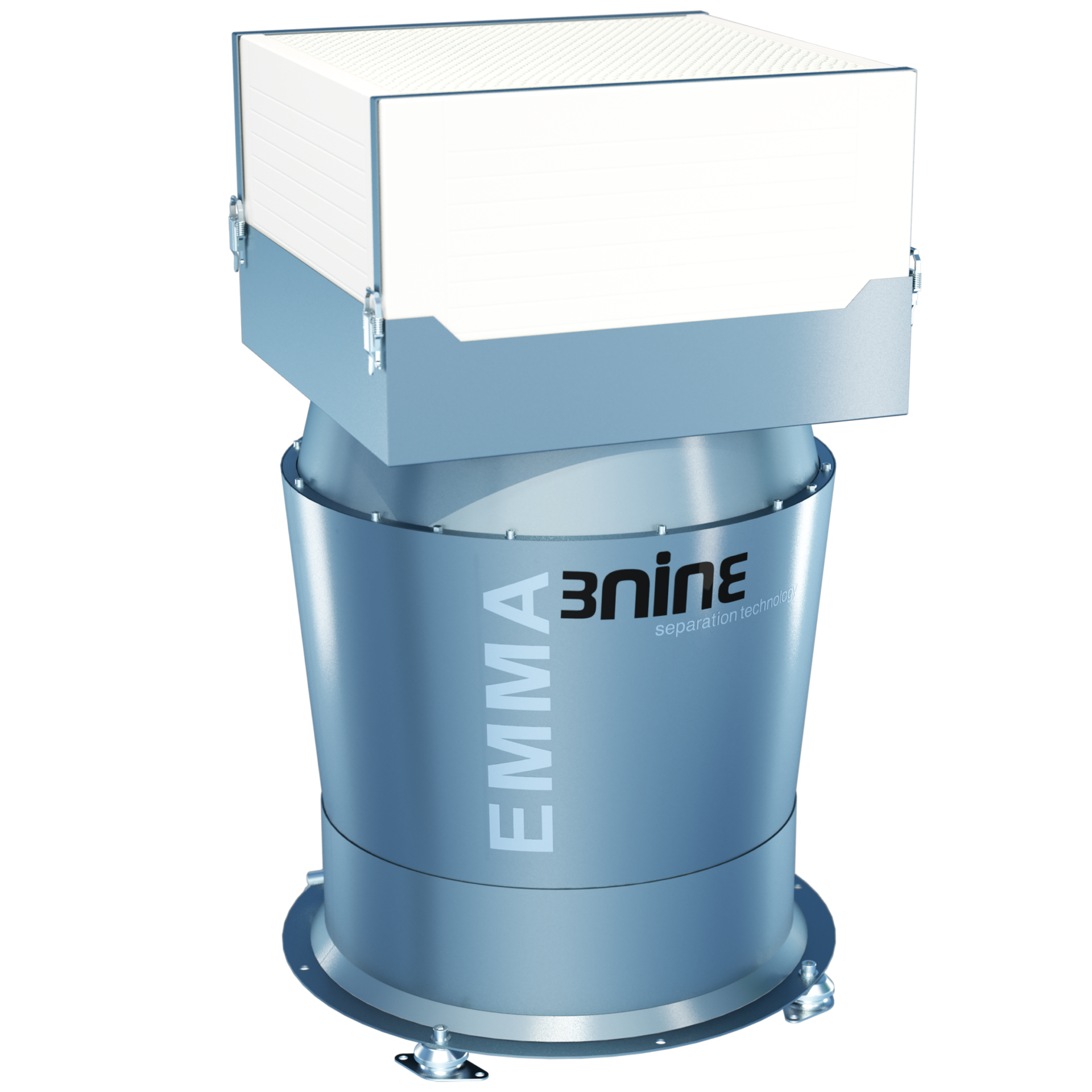

The oil mist eliminator Lina is specifically designed for enclosed machine tools, with a cabin size of 176 CF/5m³ or less.

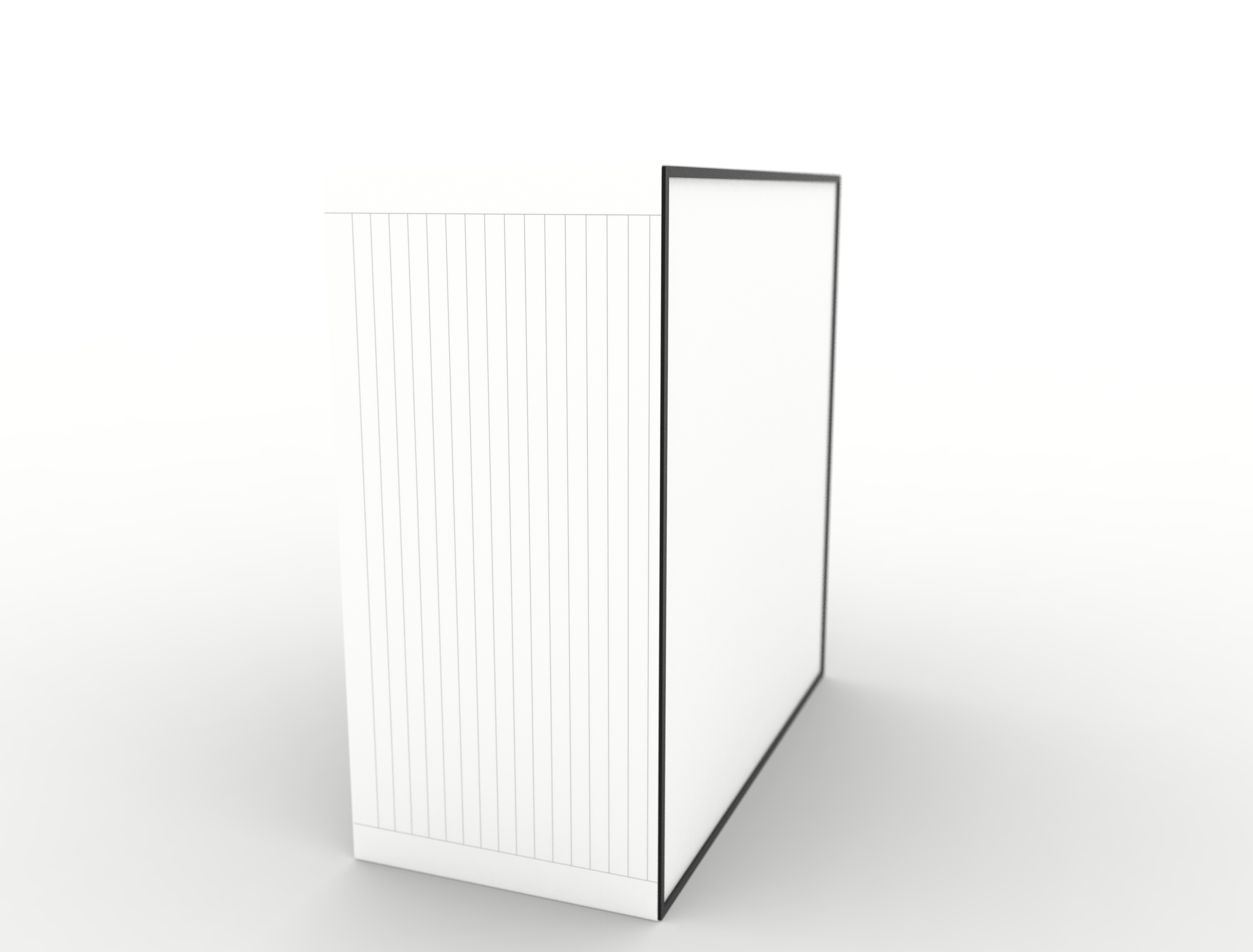

The Lina has a capacity of 300 CFM/500 m³/h and is designed to be mounted directly on top of, the side or on a stand close to the machine tool. This saves floor space and unnecessary pipe work. It also makes it easier to move the machine tool when production requirements change.

Users with small machine tools can now afford the same constant efficiency, flexibility, minimal maintenance solution offered by other 3nine products. The Lina offers unbeatable economy and a very quick ROI.

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <5m3 |

| Airflow | 500m3/h |

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <177CF |

| Airflow | 300CFM |

| Unit | Lina 500 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <5m3 |

| Airflow | 500m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 16A, 3-phase, 400V, 50Hz |

| Motor rating | 0.55kW |

| Rated current | 1.35A |

| Speed | 2790 rpm |

| Height with HEPA | 840 mm |

| Diameter | Ø 480 mm |

| Weight | 54 kg |

| Inlet pipe | Ø 125.5 mm |

| Sound level | <65 dB (A) |

| Unit | Lina 500 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <177CF |

| Airflow | 300CFM |

| Operating condition | 41-122 F |

| Electric power supply | 30/15A, 3-phase, 230/460V, 60Hz |

| Motor rating | 0.66kW |

| Rated current | 2.6A (230V) – 1.7A (460 V) |

| Speed | 3400 rpm |

| Height with HEPA | 33” |

| Diameter | Ø 18.9” |

| Weight | 119 lbs |

| Inlet pipe | Ø 5” |

| Sound level | <65 dB (A) |

The oil mist eliminator Lina is specifically designed for enclosed machine tools, with a cabin size of 176 CF/5m³ or less.

The Lina has a capacity of 300 CFM/500 m³/h and is designed to be mounted directly on top of, the side or on a stand close to the machine tool. This saves floor space and unnecessary pipe work. It also makes it easier to move the machine tool when production requirements change.

Users with small machine tools can now afford the same constant efficiency, flexibility, minimal maintenance solution offered by other 3nine products. The Lina offers unbeatable economy and a very quick ROI.

| Unit | Lina 500 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <5m3 |

| Airflow | 500m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 16A, 3-phase, 400V, 50Hz |

| Motor rating | 0.55kW |

| Rated current | 1.35A |

| Speed | 2790 rpm |

| Height with HEPA | 840 mm |

| Diameter | Ø 480 mm |

| Weight | 54 kg |

| Inlet pipe | Ø 125.5 mm |

| Sound level | <65 dB (A) |

| Unit | Lina 500 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <177CF |

| Airflow | 300CFM |

| Operating condition | 41-122 F |

| Electric power supply | 30/15A, 3-phase, 230/460V, 60Hz |

| Motor rating | 0.66kW |

| Rated current | 2.6A (230V) – 1.7A (460 V) |

| Speed | 3400 rpm |

| Height with HEPA | 33” |

| Diameter | Ø 18.9” |

| Weight | 119 lbs |

| Inlet pipe | Ø 5” |

| Sound level | <65 dB (A) |

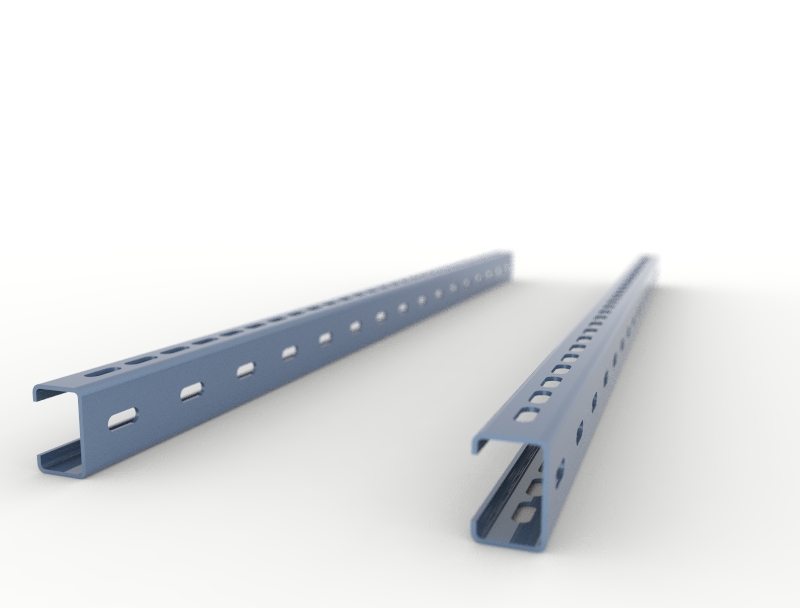

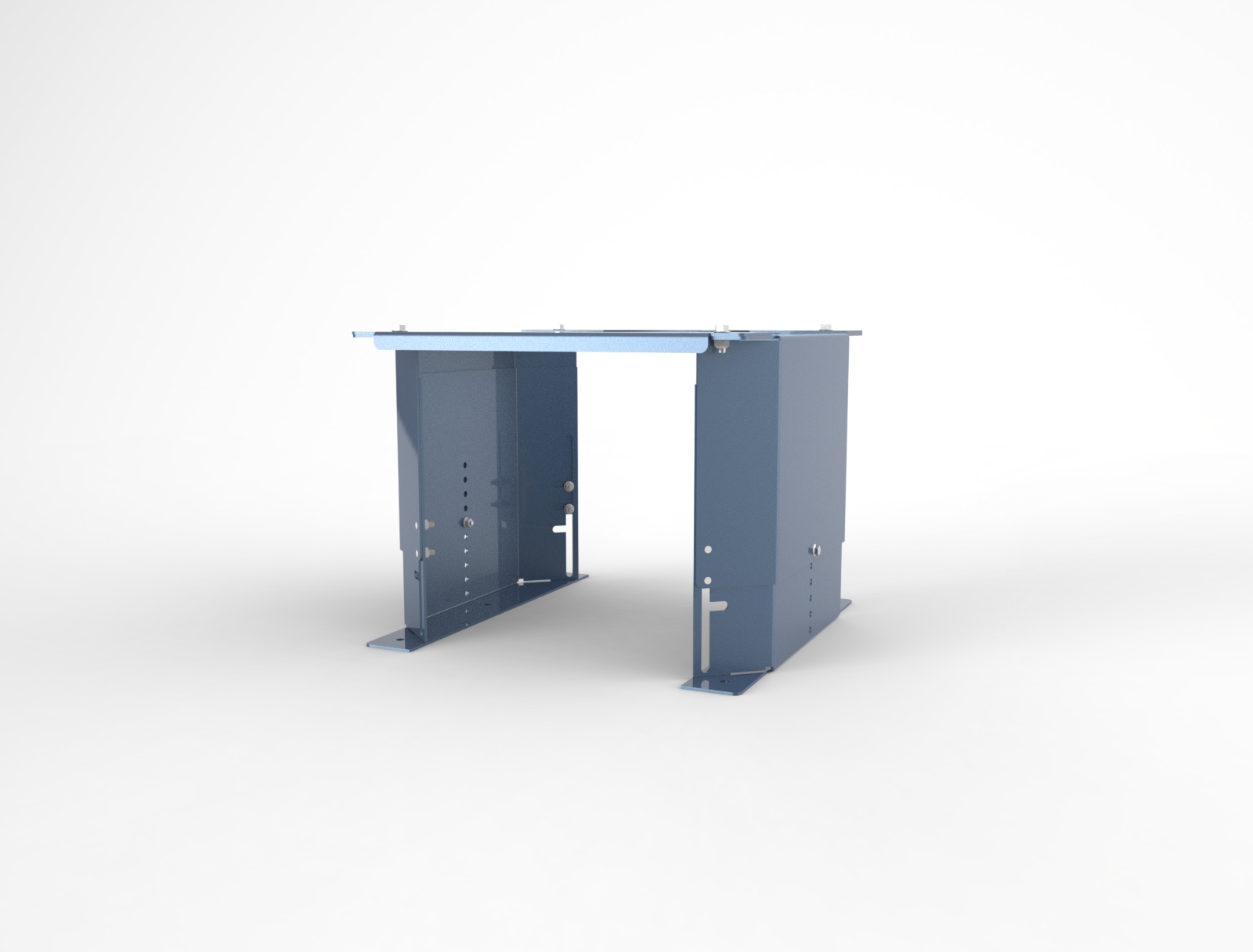

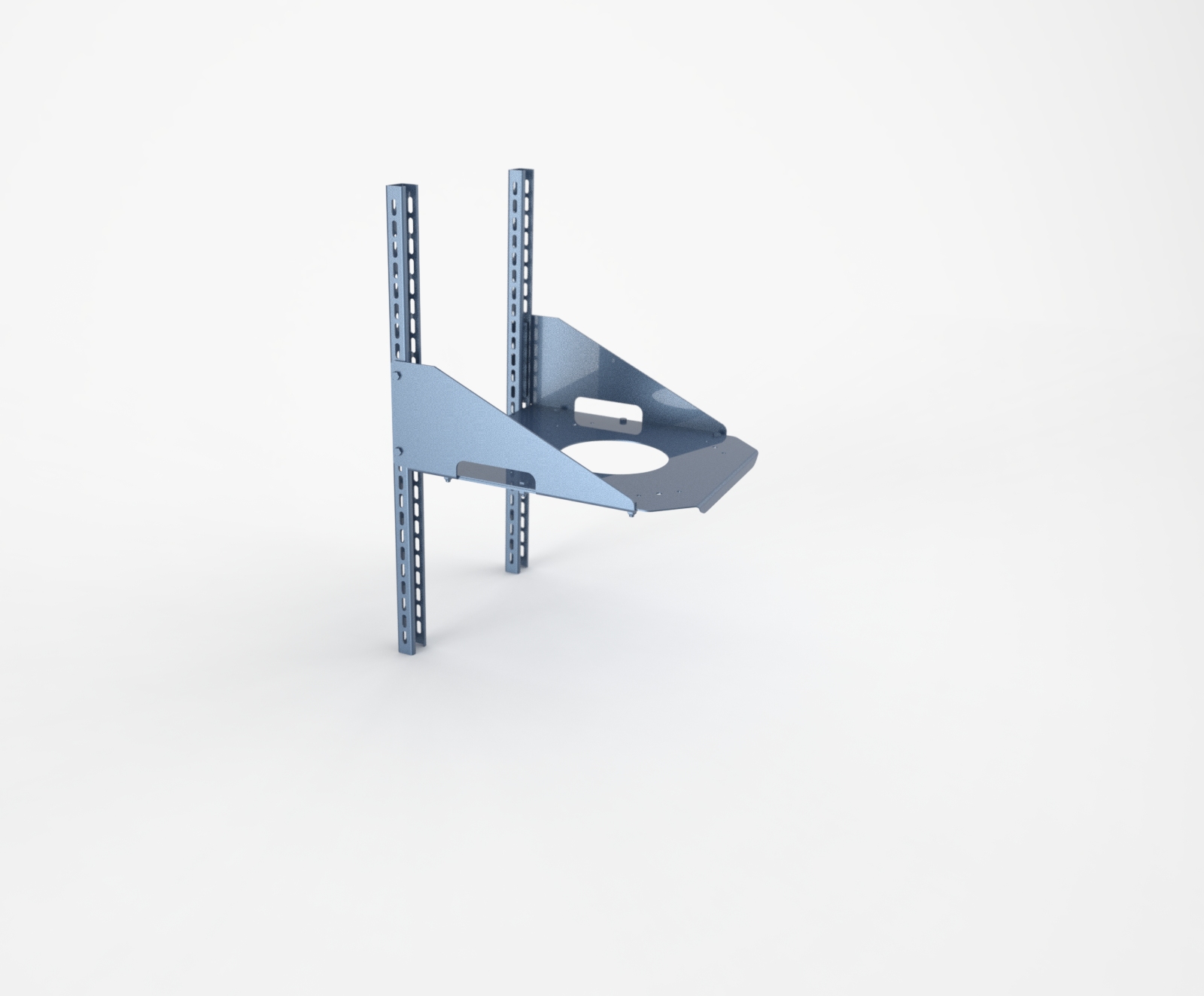

Accessories and spare parts

Installation images

Bargo Engineering Inc., USA

”Upon first hearing about the technology, we thought this was just another mist collector. We have tried others in the past that worked for a short time and clogged up with cutting fluid and did very little to improve the air quality. The 3nine Mist Separator however, have a very high purification rate and minimum filter replacement (2 years with one filter). The machine operator as well as other staff members have noticed a significant improvement in the air quality. Thank you for introducing us to the 3nine product line.”