Clara 1000

The Clara oil mist separator is designed to suit a wide range of machine tools, with cabin sizes up to 353 CF (10 m³).

It effectively captures oil mist during machining, returning clean air to the workshop while maximizing the reuse of valuable oils and coolants.

With co-current technology, Clara achieves exceptional separation efficiency, removing 99.9% of oil mist particles down to 1μm. Designed for easy maintenance and reliable operation, Clara ensures a cleaner, healthier work environment while reducing waste.

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

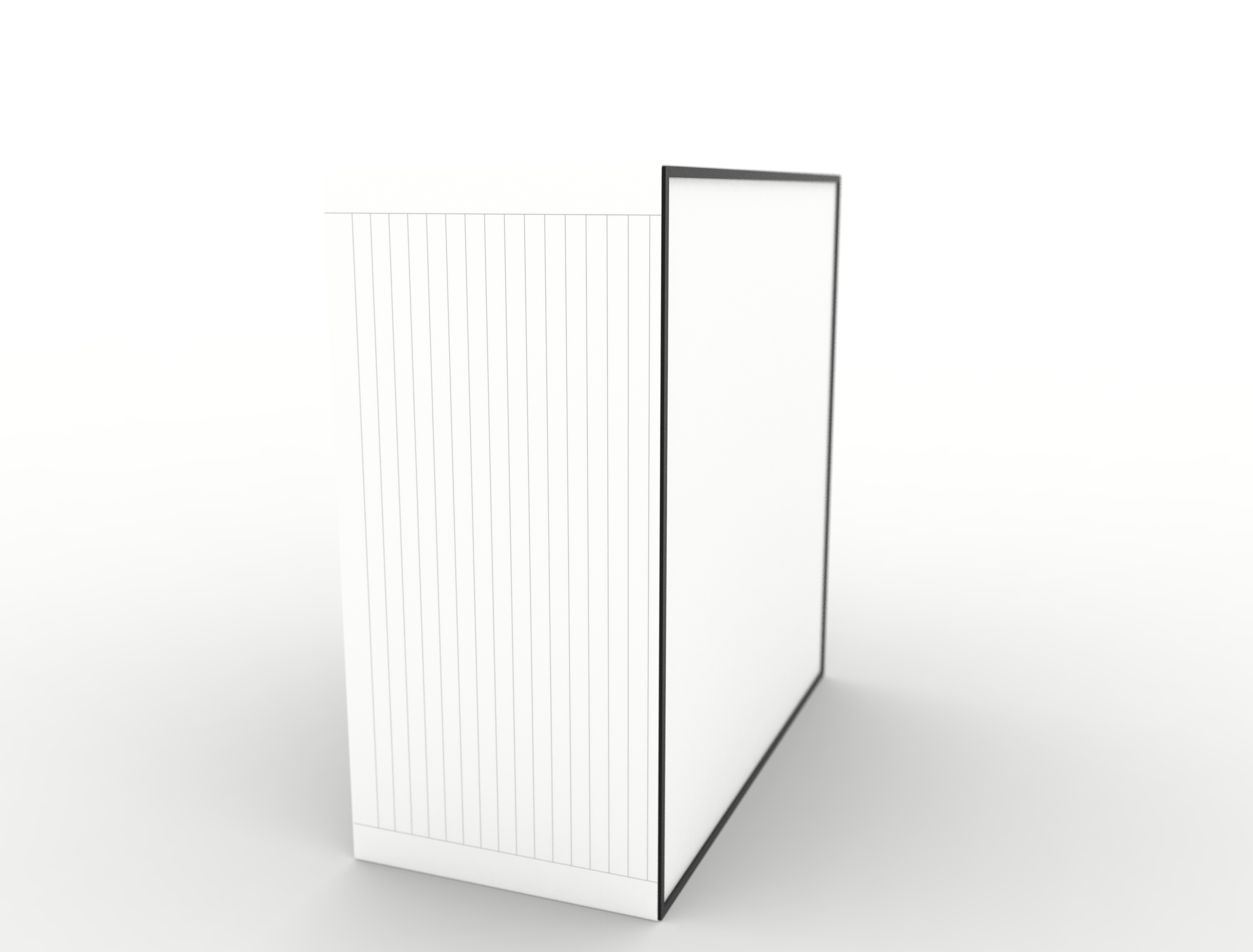

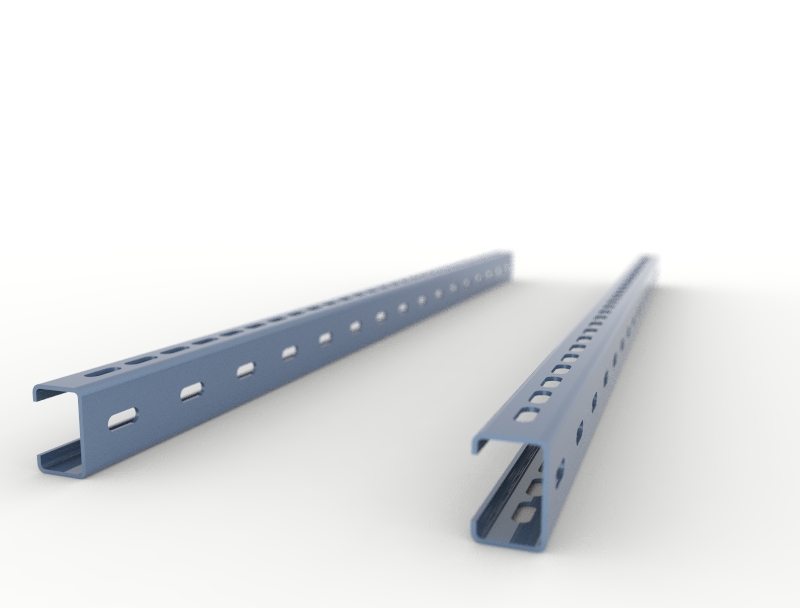

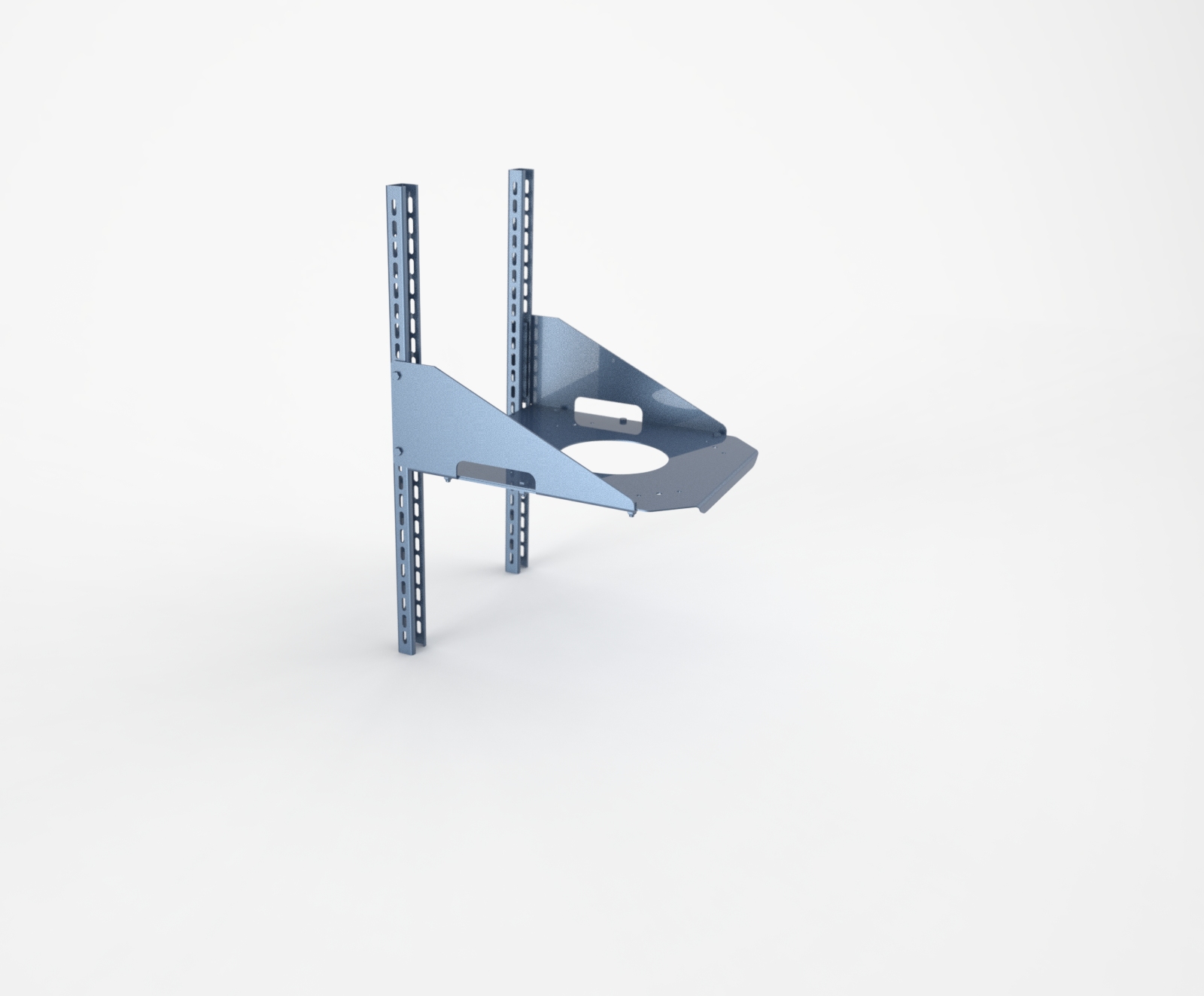

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <10m3 |

| Airflow | 1000m3/h |

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <353CF |

| Airflow | 600CFM |

| Unit | Clara 1000 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <10m3 |

| Airflow | 1000m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 16A, 3-phase, 400V, 50Hz |

| Motor rating | 1.5kW |

| Rated current | 3.2A |

| Speed | 2835 rpm |

| Height with HEPA | 1145 mm |

| Diameter | Ø 640 mm |

| Weight | 89 kg |

| Inlet pipe | Ø 161 mm |

| Sound level | <65 dB (A) |

| Unit | Clara 1000 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <353CF |

| Airflow | 600CFM |

| Operating condition | 41-122 F |

| Electric power supply | 30/15A, 3-phase, 230/460V, 60Hz |

| Motor rating | 1.5kW |

| Rated current | 5.6A (230V) – 3.6A (460 V) |

| Speed | 3440 rpm |

| Height with HEPA | 45” |

| Diameter | Ø 25” |

| Weight | 196 lbs |

| Inlet pipe | Ø 6” |

| Sound level | <65 dB (A) |

The Clara oil mist separator is designed to suit a wide range of machine tools, with cabin sizes up to 353 CF (10 m³).

It effectively captures oil mist during machining, returning clean air to the workshop while maximizing the reuse of valuable oils and coolants.

With co-current technology, Clara achieves exceptional separation efficiency, removing 99.9% of oil mist particles down to 1μm. Designed for easy maintenance and reliable operation, Clara ensures a cleaner, healthier work environment while reducing waste.

| Unit | Clara 1000 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <10m3 |

| Airflow | 1000m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 16A, 3-phase, 400V, 50Hz |

| Motor rating | 1.5kW |

| Rated current | 3.2A |

| Speed | 2835 rpm |

| Height with HEPA | 1145 mm |

| Diameter | Ø 640 mm |

| Weight | 89 kg |

| Inlet pipe | Ø 161 mm |

| Sound level | <65 dB (A) |

| Unit | Clara 1000 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <353CF |

| Airflow | 600CFM |

| Operating condition | 41-122 F |

| Electric power supply | 30/15A, 3-phase, 230/460V, 60Hz |

| Motor rating | 1.5kW |

| Rated current | 5.6A (230V) – 3.6A (460 V) |

| Speed | 3440 rpm |

| Height with HEPA | 45” |

| Diameter | Ø 25” |

| Weight | 196 lbs |

| Inlet pipe | Ø 6” |

| Sound level | <65 dB (A) |

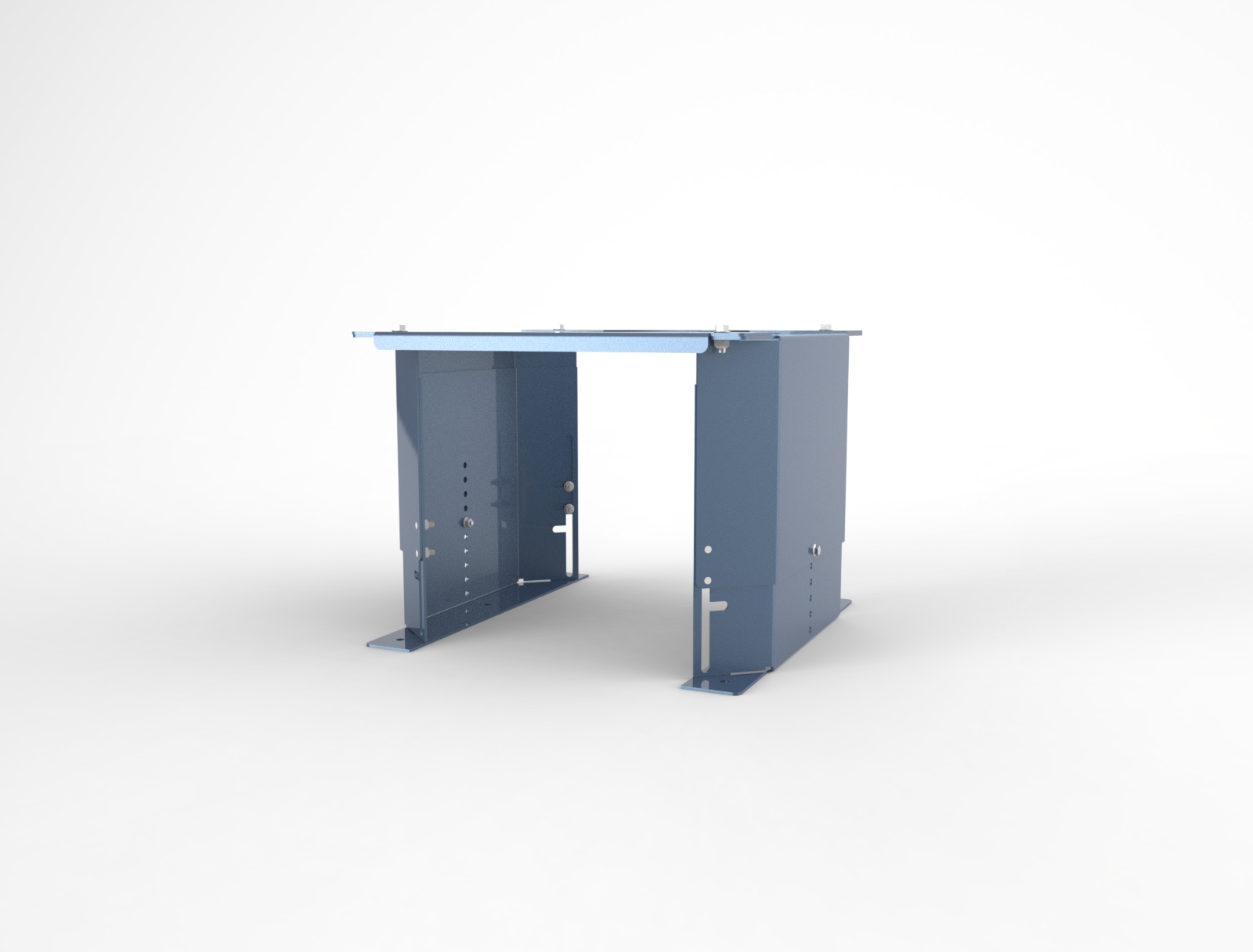

Installation images

Eickhoff Maschinenfabrik GmbH, Germany

“Due to 3nine’s innovative technology we can keep our maintenance costs on a low level.”