Nina 1200

The oil mist eliminator Nina is specially designed for higher airflow and works on all machine tools with a cabin volume up to 424 CF (12 m³).

The Nina effectively cleans the oil mist formed during the machining process and provides clean air into the workshop, as well as recycling almost all of your oil/coolant from the mist.

The Nina is suitable for all applications involving processes using oil, coolants or other lubricants. Even with tough applications such as grinding and machining of cast iron you can expect 99.95% particle free air. Read more about how this is possible under the Technology section.

See examples of how others have installed their Nina oil mist eliminator under “Installation Images” further down on this page.

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <12m3 |

| Airflow | 1200m3/h |

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <425CF |

| Airflow | 704CFM |

| Unit | Nina 1200 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <12m3 |

| Airflow | 1200m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 3-phase, 380-480V, 50/60Hz, 6A |

| Motor rating | 1.5kW |

| Rated current | 3.3A |

| Speed | 6700 rpm |

| Lenght | 777 mm |

| Depth | 833 mm |

| Height | 936 mm |

| Weight | 119 kg |

| Inlet pipe | Ø 200 mm |

| Sound level | <70 db (A) |

| Unit | Nina 1200 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <425CF |

| Airflow | 704CFM |

| Operating condition | 41-122 F |

| Electric power supply | 3-phase, 208-240V, 50/60Hz, 6A |

| Motor rating | 1.5kW |

| Rated current | 2.8A (230V) – 5.7A (460V) |

| Speed | 6700 rpm |

| Lenght | 30.5” |

| Depth | 32.8” |

| Height | 36.9” |

| Weight | 262.4 lbs |

| Inlet pipe | Ø 8” |

| Sound level | <70 db (A) |

The oil mist eliminator Nina is specially designed for higher airflow and works on all machine tools with a cabin volume up to 424 CF (12 m³).

The Nina effectively cleans the oil mist formed during the machining process and provides clean air into the workshop, as well as recycling almost all of your oil/coolant from the mist.

The Nina is suitable for all applications involving processes using oil, coolants or other lubricants. Even with tough applications such as grinding and machining of cast iron you can expect 99.95% particle free air. Read more about how this is possible under the Technology section.

See examples of how others have installed their Nina oil mist eliminator under “Installation Images” further down on this page.

| Unit | Nina 1200 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <12m3 |

| Airflow | 1200m3/h |

| Operating condition | 5-50°C |

| Electric power supply | 3-phase, 380-480V, 50/60Hz, 6A |

| Motor rating | 1.5kW |

| Rated current | 3.3A |

| Speed | 6700 rpm |

| Lenght | 777 mm |

| Depth | 833 mm |

| Height | 936 mm |

| Weight | 119 kg |

| Inlet pipe | Ø 200 mm |

| Sound level | <70 db (A) |

| Unit | Nina 1200 |

|---|---|

| Application | Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

| Mounting | Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size | <425CF |

| Airflow | 704CFM |

| Operating condition | 41-122 F |

| Electric power supply | 3-phase, 208-240V, 50/60Hz, 6A |

| Motor rating | 1.5kW |

| Rated current | 2.8A (230V) – 5.7A (460V) |

| Speed | 6700 rpm |

| Lenght | 30.5” |

| Depth | 32.8” |

| Height | 36.9” |

| Weight | 262.4 lbs |

| Inlet pipe | Ø 8” |

| Sound level | <70 db (A) |

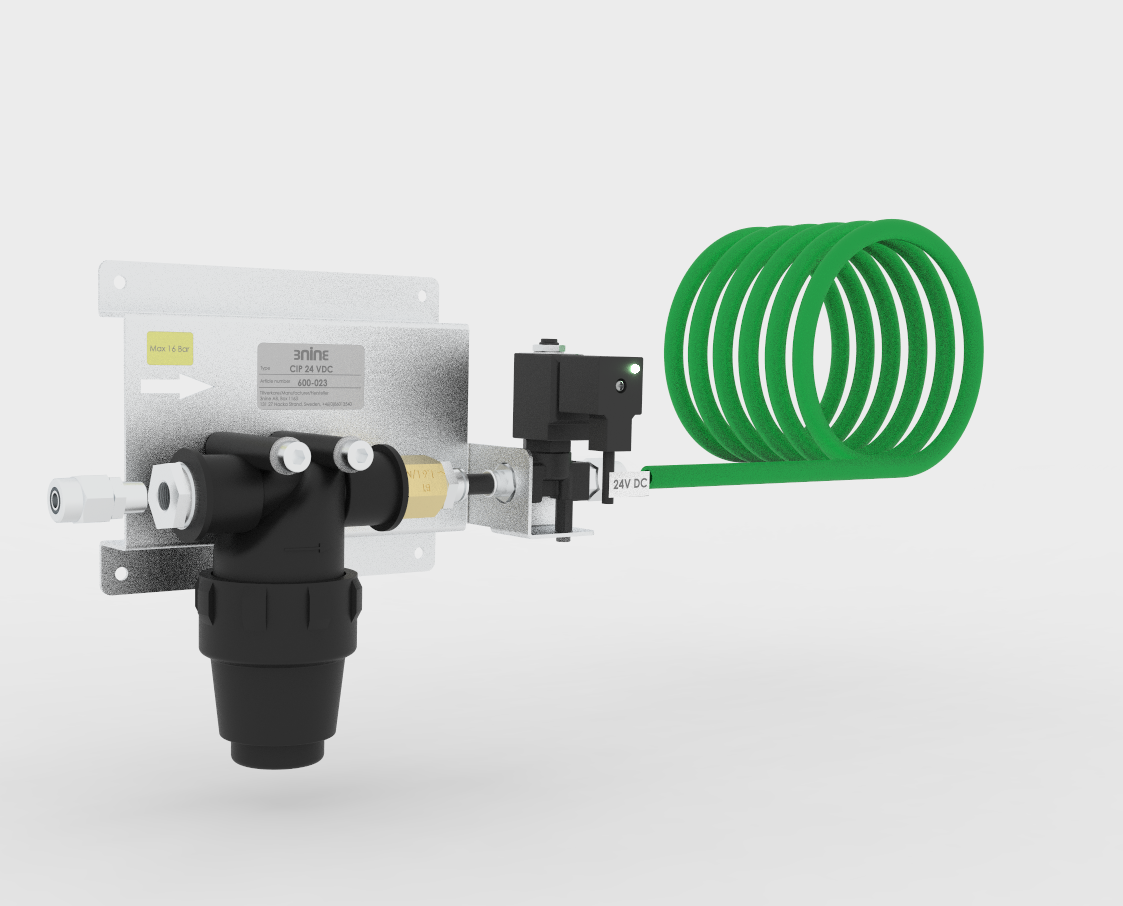

Accessories and spare parts

Installation images

Hemabo, The Netherlands

"The mist in the shop is gone. We can actually see across the room and you significantly feel a better air quality."